It takes time and experience to move fast. Efficiency that doesn’t compromise on quality is something we pride ourselves on. This is why our quality and manufacturing engineers oversee every detail of a product, ensuring that high speed doesn’t come at the cost of high quality. Similarly, our design engineers contribute novel solutions for manufacturing methods and equipment, helping each product enjoy a smooth ride to the finish line.

What we do

Precision Mold Making

Precision Mold Making

Plastics are at the heart of all Hayco products. Once a mold is made and qualifies, it is implemented in one of our 300 specialised machines from Europe and Japan. We offer expertise in 2K molding, high cavitation and automation, in-mold labelling (IML), gas-assist molding, silicone LIM, stack molds and more.

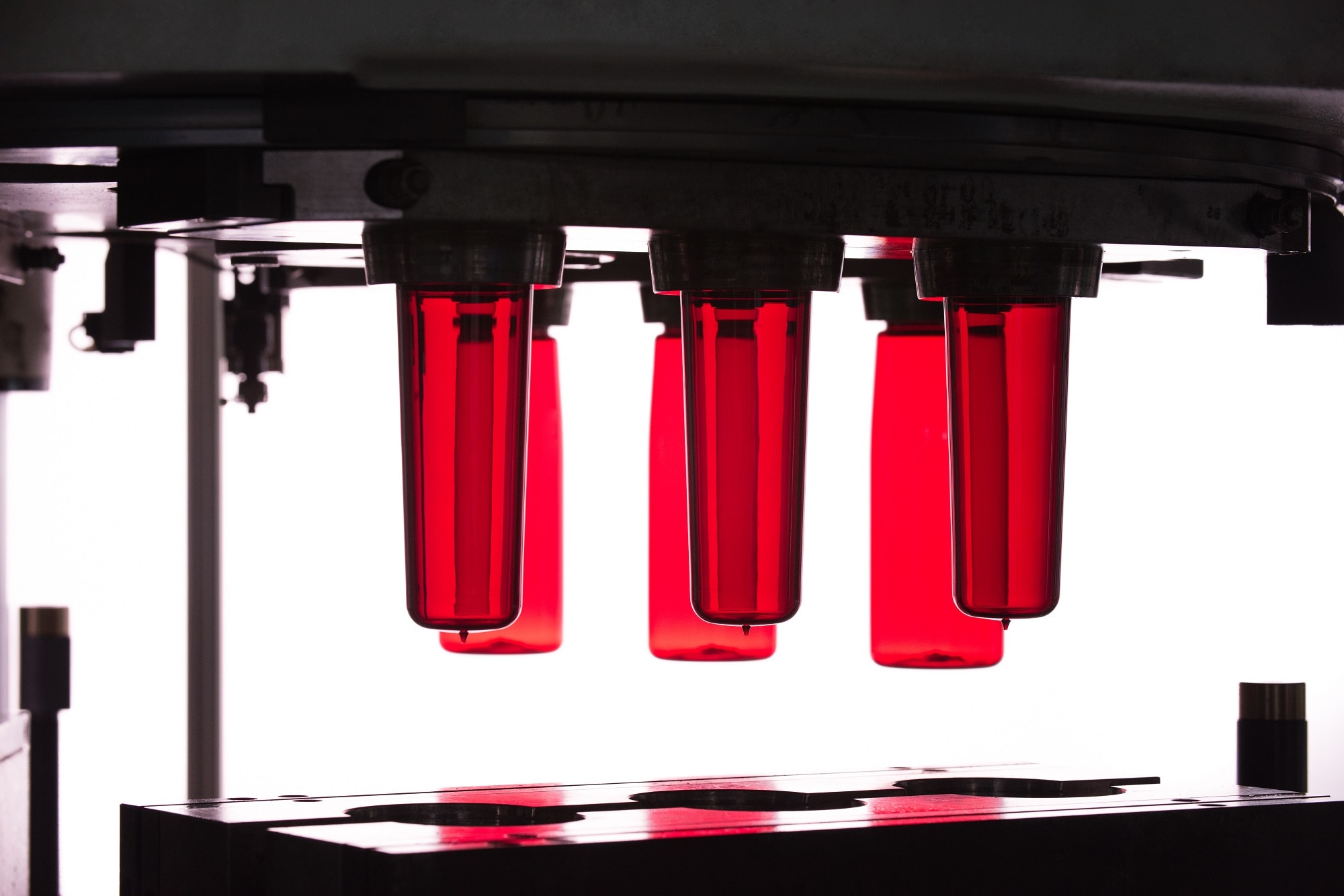

Injection molding

Injection molding

For multi-purpose container molding that depends on precision heat conditioning, we offer unique Injection Stretch Blow Molding (ISBM) technology. Silicone rubber, valued in the medical, baby and electronics sectors for its versatility, is handled by our Silicone Liquid Injection Molding (LIM) capabilities. To incorporate labelling and decoration directly into the injection-molding process, we offer the opportunity for customisation through our In-Mold Labeling (IML) services.

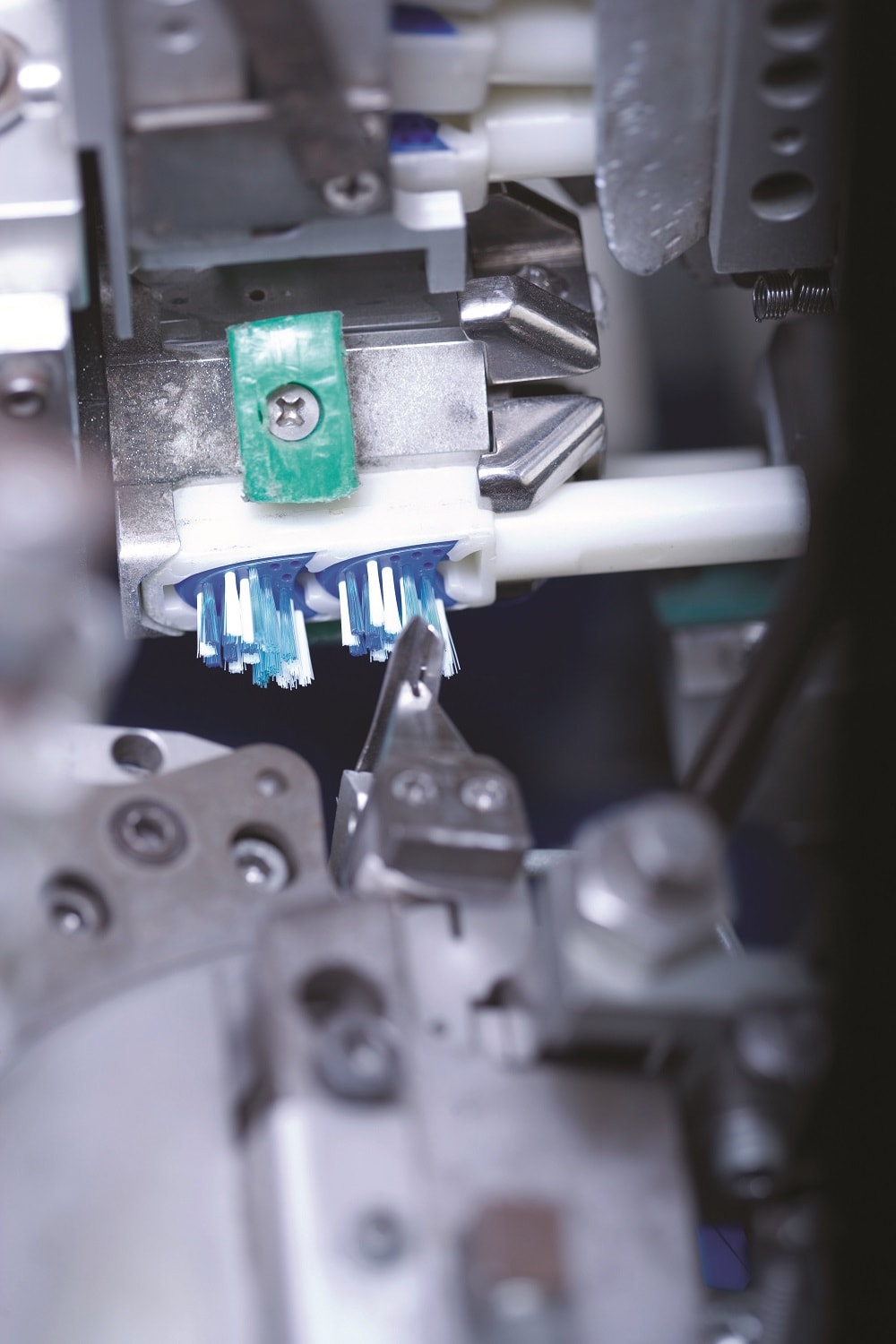

Brush-making

Brush-making

Our heritage is rooted in brush-making, characterizing us as a long-standing leader in this sector. Our high-speed bristling capabilities and output volume are supported by strict product validation and testing. We continue to invest in the latest equipment from Germany and Italy to improve quality and efficiency across the board.

Assembly

Assembly

We prioritise speed, accuracy and quality control in our assembly processes. Our automated assembly technologies and comprehensive worker training programmes are the foundation of our solutions. These include printed circuit board (PCB) and electronic sensing devices assembly; metal fabrication; sonic, laser and hot plate welding as well as advanced surface decoration.

Quality control

Quality control

Monitoring both functional and cosmetic assessments, we conduct a full-suite of evaluations to ensure quality, safety and performance. We’re committed to validation processes through our five quality gates: incoming quality control, in-process quality control, line quality control, final quality audit and customer pre-shipment inspection.